SAV Vilaró follows a series of internal traceability processes to take care of the quality of each one of its projects and to improve production processes. Our aim is to offer an excellent service, free of anomalies.

The Sant Julià de Vilatorta company follows an exhaustive internal quality method in order to offer its best version of the manufacturing process. The company follows its own internal protocols that aim for zero error.

Quality control to achieve excellent results

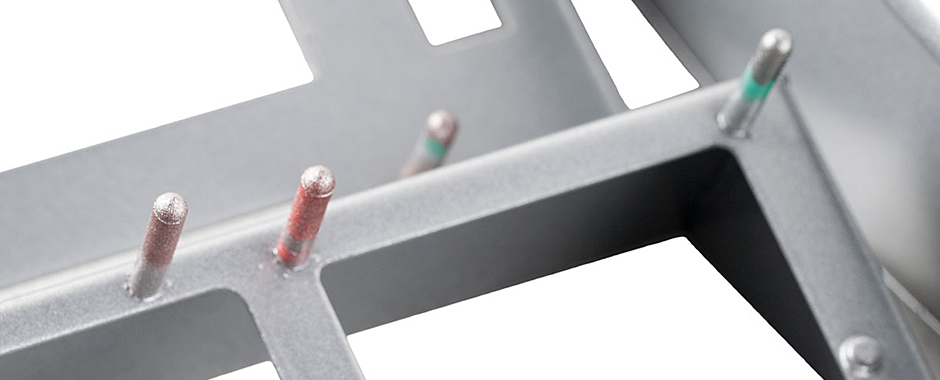

SAV Vilaró combines experience, knowledge and technology to guarantee an optimum quality in its production processes. Throughout the entire process the company follows manufacturing guidelines that guarantee quality control and monitoring.

From beginning to end, SAV Vilaró follows a carefully recorded manufacturing process, in which each production process confirms the work done by the previous one, and, at the same time, checks it with the technical documentation.

The production processes of SAV Vilaró follow established guidelines and are organised so that customers can have traceability of their product at any time and at any point in the process.

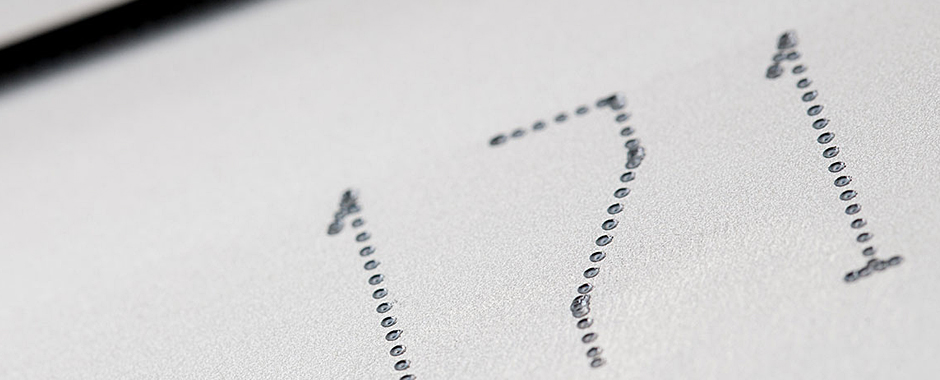

SAV Vilaró documents and records the entire process to guarantee quality and help to detect new issues and/or anomalies.

SAV Vilaró works with an ERP programme that integrates the different production processes to guarantee maximum quality and minimise errors. Throughout the production process SAV Vilaró generates technical information of great benefit to improve production processes.

SAV Vilaró follows internal traceability processes to improve production processes.